zhenying · We will carefully select products for you!

product center

Vibrating Screens

Conveying & grading

Lab Testing Sieve

Screen & Parts

-

Circular Vibrating Screen

Circular Vibrating ScreenGet Quote:15993065963

Circular Vibrating ScreenGet Quote:15993065963

High quality, low price, more to meet your needsMORE -

Multi Frequency Screen

Multi Frequency ScreenGet Quote:15993065963

Multi Frequency ScreenGet Quote:15993065963

High quality, low price, more to meet your needsMORE -

Ultrasonic Powder Sieving Machine

Ultrasonic Powder Sieving MachineGet Quote:15993065963

Ultrasonic Powder Sieving MachineGet Quote:15993065963

High quality, low price, more to meet your needsMORE -

Rectangular Vibrating Screen

Rectangular Vibrating ScreenGet Quote:15993065963

Rectangular Vibrating ScreenGet Quote:15993065963

High quality, low price, more to meet your needsMORE -

Tumbler Screen Round Circular

Tumbler Screen Round CircularGet Quote:15993065963

Tumbler Screen Round CircularGet Quote:15993065963

High quality, low price, more to meet your needsMORE -

Gyratory Screening Machines

Gyratory Screening MachinesGet Quote:15993065963

Gyratory Screening MachinesGet Quote:15993065963

High quality, low price, more to meet your needsMORE

-

Belt Conveyor Production Line

Belt Conveyor Production LineGet Quote:15993065963

Belt Conveyor Production LineGet Quote:15993065963

High quality, low price, more to meet your needsMORE -

Electromagnetic Vibratory Pan Feeder

Electromagnetic Vibratory Pan FeederGet Quote:15993065963

Electromagnetic Vibratory Pan FeederGet Quote:15993065963

High quality, low price, more to meet your needsMORE -

Grinder Machine

Grinder MachineGet Quote:15993065963

Grinder MachineGet Quote:15993065963

High quality, low price, more to meet your needsMORE -

Portable Belt Conveyor

Portable Belt ConveyorGet Quote:15993065963

Portable Belt ConveyorGet Quote:15993065963

High quality, low price, more to meet your needsMORE -

Screw Conveyor

Screw ConveyorGet Quote:15993065963

Screw ConveyorGet Quote:15993065963

High quality, low price, more to meet your needsMORE -

Vacuum Conveyor

Vacuum ConveyorGet Quote:15993065963

Vacuum ConveyorGet Quote:15993065963

High quality, low price, more to meet your needsMORE

-

Vibrator

VibratorGet Quote:15993065963

VibratorGet Quote:15993065963

High quality, low price, more to meet your needsMORE -

Warehouse Wall Vibrator

Warehouse Wall VibratorGet Quote:15993065963

Warehouse Wall VibratorGet Quote:15993065963

High quality, low price, more to meet your needsMORE -

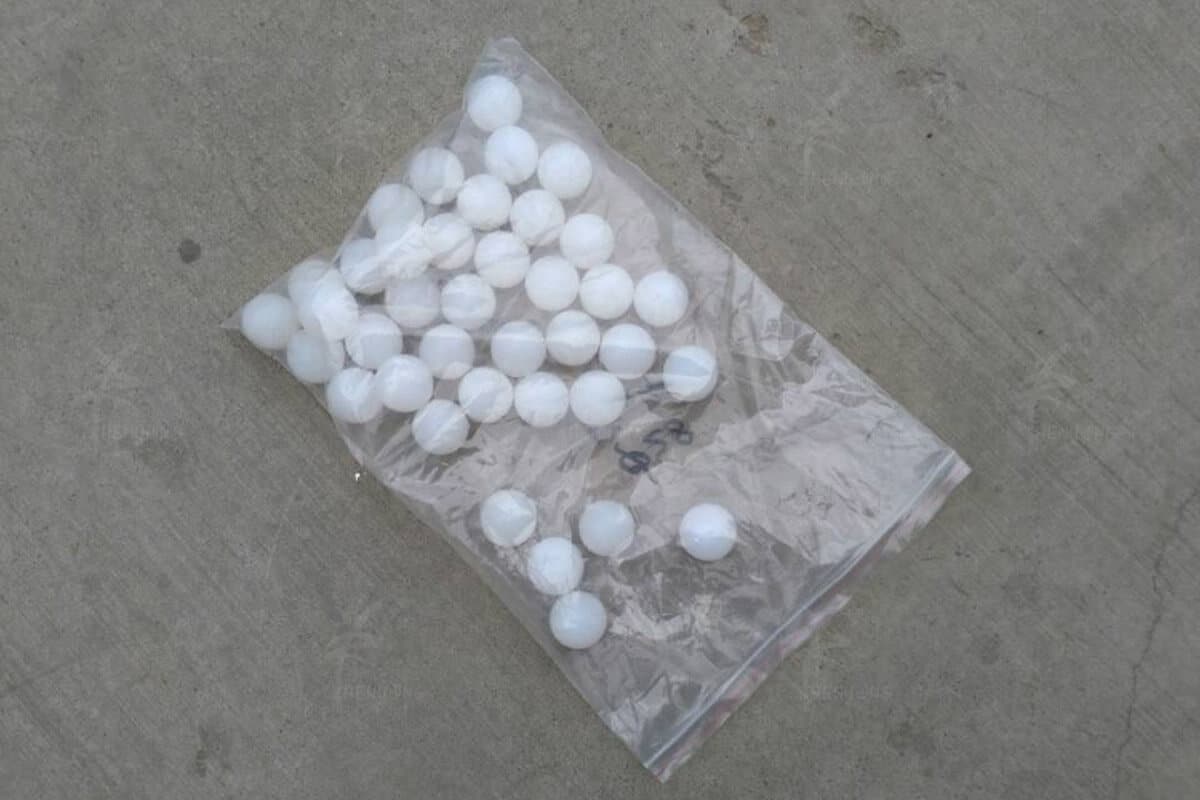

Bouncing Ball

Bouncing BallGet Quote:15993065963

Bouncing BallGet Quote:15993065963

High quality, low price, more to meet your needsMORE -

Horizontal Electric Motor

Horizontal Electric MotorGet Quote:15993065963

Horizontal Electric MotorGet Quote:15993065963

High quality, low price, more to meet your needsMORE -

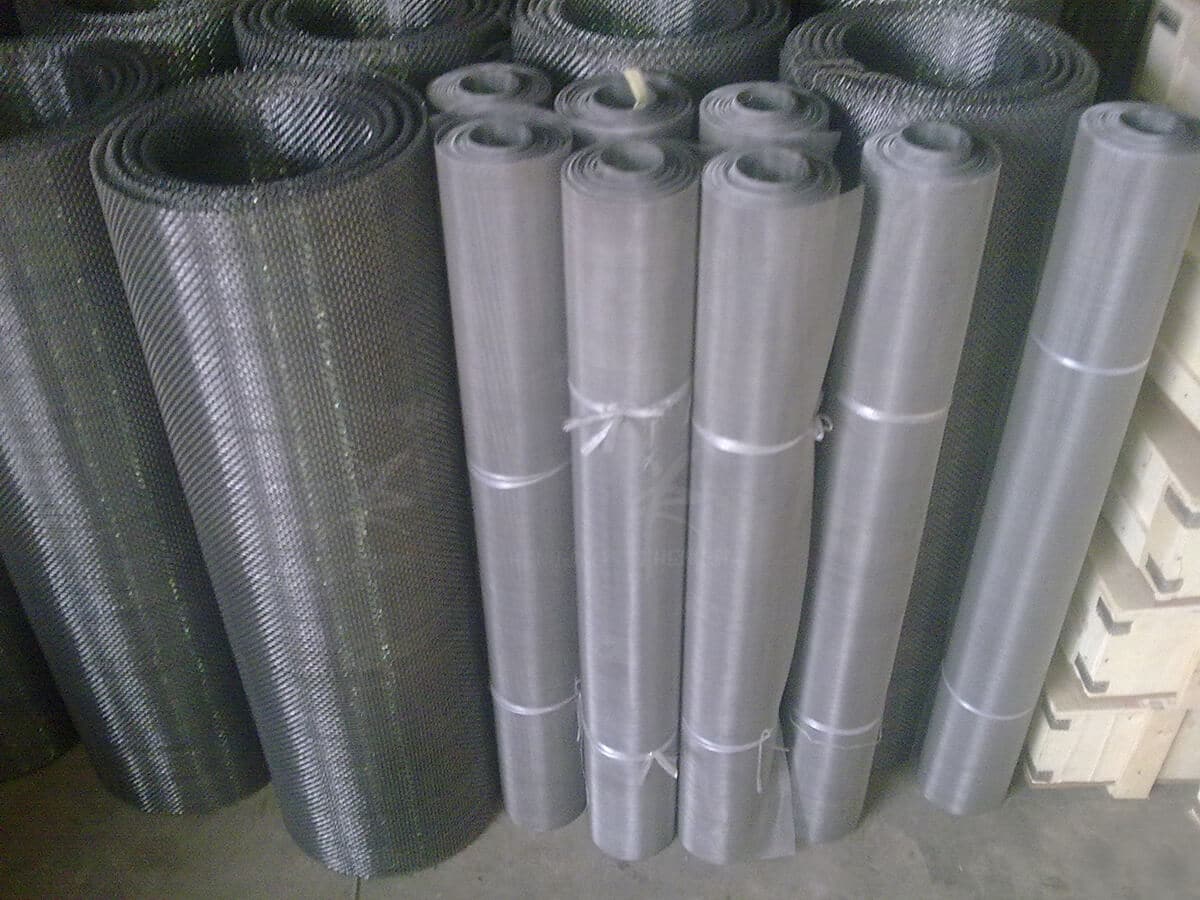

Screen Mesh

Screen MeshGet Quote:15993065963

Screen MeshGet Quote:15993065963

High quality, low price, more to meet your needsMORE -

Sealing Ring

Sealing RingGet Quote:15993065963

Sealing RingGet Quote:15993065963

High quality, low price, more to meet your needsMORE

豫公网安备 41070202000471号

豫公网安备 41070202000471号